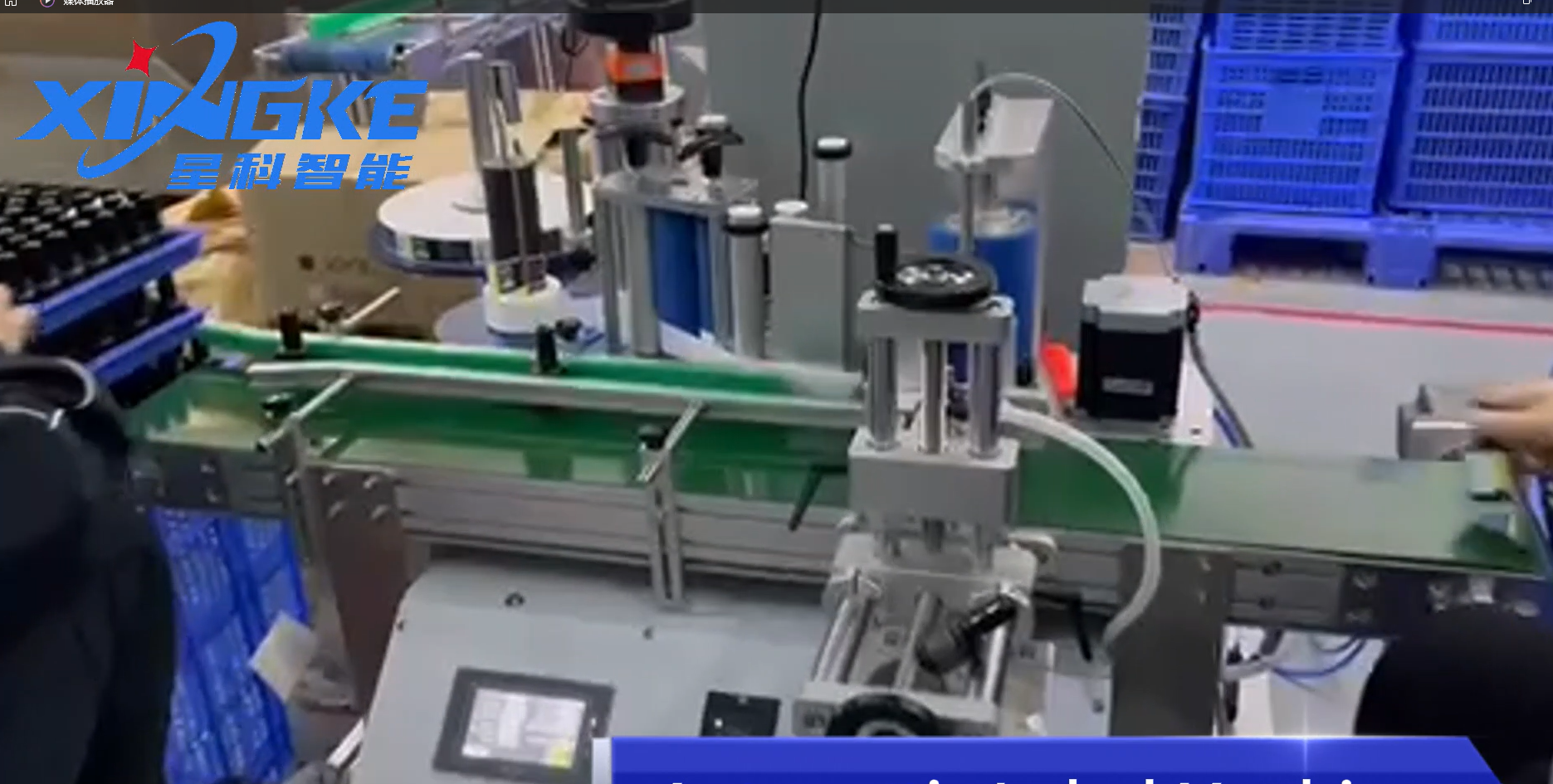

Xingke Machine - Professional Automatic Packing Machine Manufacturer with 15+ years production experience.

Automatic label machine Products | Xingke

Product Introduction

The main working mechanism of the labeling machine consists of several parts, including a label supply device, a label removal device, a printing device (if necessary), a gluing device and an interlocking device. Among them, the label supply device is responsible for supplying the label paper according to certain process requirements during the labeling process.

3. Working principle

The working principle of the labeling machine usually involves the following steps:

1. The box or container is fed to the labeling machine at a constant speed on the conveyor belt.

2. The mechanical fixing device separates the boxes or containers by a fixed distance and pushes them forward in the direction of the conveyor belt.

3. The driving wheel intermittently drags the label tape to move, and the label tape is pulled out from the reel and passes through the labeling wheel at the same time.

The labeling wheel presses the label tape on the box or container when the box or container moves at the same speed as the label tape.

The registration mark on the label tape is read by the sensor. To ensure that each label is placed correctly.

4. During the deceleration stage of the label tape, the driving wheel will readjust the position to correct any position error on the label tape

As an important part of modern packaging, labeling machines play an important role in improving production efficiency, ensuring label quality and enhancing product image.

Company Advantages

Expansion functions can be added, such as coding, labeling, punching, cursor positioning, etc.The equipment parts are made with advanced technology such as CNC lathes, and laser cutting.

Provide design and drawings (3D/2D simulation) Provide CE.

One-To-One customer service and engineer solution and free sample.The equipment is aimed at a wide range of industries and is widely used in many manufacturing industries such as furniture, bathroom, lighting, hardware, auto parts, etc.

Experienced team and after-sales engineers provide One-To-One service.

Quick Links

Automatic Packaging Machine Products

Contact Xingke Automatic Packaging Machine Manufacturer

Contact: Mr Ren

Contact: Mr Ren

Email: office@xingkepacking.com

Email: office@xingkepacking.com Tel.: +86 13318294551

Tel.: +86 13318294551

Add: 9/F, Zhongchuang Industrial Park, No. 1 Xiaowusong Road, Huoju Development Zone, Zhongshan, Guangdong , China

Add: 9/F, Zhongchuang Industrial Park, No. 1 Xiaowusong Road, Huoju Development Zone, Zhongshan, Guangdong , China

Please Contact Us.

Xingke Machine is the professional automatic packaging equipment manufacturing expert.