Xingke Machine - Professional Automatic Packing Machine Manufacturer with 15+ years production experience.

Top 5 Features to Look for in a Fastener Packing Machine

Would a poorly packaged item look attractive enough for you to buy it? Not really. Hence, in the industry and hardware, proper packaging is vital, and acquiring the proper fasteners packing machine is a great advantage for manufacturers.

Fasteners like nuts, bolts, and screws require good packing for efficient delivery and also in good order. As the number of models and functionalities keeps increasing, it is becoming more difficult to choose the right machine for the needs of your operations.

This article will showcase the top 5 features of a fastener packing machine that will help you make an informed decision about the purchase of the machine.

1. Speed and Efficiency

One of the most crucial features of a fastener packaging machine is its speed. Time is money in any manufacturing process, and you want a machine that can package fasteners at a rapid pace without compromising accuracy. Look for machines with high throughput rates, measured in units packaged per minute.

Good fastener-packing machines must be able to pack in bulk volumes of fasteners while maintaining precision in sorting, counting, and sealing effectiveness. Including automation features like robotic arms or automatic loaders increases the work rate and reduces human intervention, thus optimizing performance.

When you invest in a machine with such high-speed capabilities, you guarantee the smooth running of your packaging lines!

2. Precision and Accuracy

A fastener packaging machine design should be done in such a way that it correctly counts and sorts fasteners to eliminate the tendency of either over or under-packing. Many hi-tech packaging machines today possess in-built sensing devices operated by computer systems that facilitate the correct packing of the required fasteners.

Additionally, accuracy is vital for quality control, as incorrect packaging can lead to customer dissatisfaction and potential financial losses. A machine with an automatic checking device and well-structured accurate sortation mechanism maintains a steady high standard of packaging quality.

3. Versatility

Dive deeper into versatility while looking for fasteners. Many fasteners have different shapes and sizes as well as different materials used. The best fastener packing machine for fasteners should be sufficient to pack different types. Such machines increase speed by offering operational flexibility by not changing fastener components after every packing.

A few devices include some frames with interchangeable fasteners or settings that help the user operate different fastening appliances quite easily. This flexibility may also include other types of packaging, such as bags, boxes, or pouches, to meet different customer needs and packaging preferences.

4. Durability and Reliability

A fastener packing machine buying guide is incomplete without including the reliability and quality of materials of the machine. Given that packing machines are long term investments, you need one that can withstand constant use. Machines made entirely with stainless steel or those with heavy plastic parts have better performance in terms of durability.

Reliability in a machine is necessary so that there are no unnecessary downtimes because of repairs or maintenance. In assessing a machine for purchase, check its frequency of repairs and its ease of obtaining parts for replacement. Any equipment that operates smoothly and continuously with very little maintenance contributes positively to the overall efficiency of operations.

5. User-Friendly Interface and Software Integration

Increasingly, modern fastener packaging machines are at times fitted with control panels and software of high standard that facilitate better control and adjustments of the same. Since a graphical user interface is easy to use, the design, the operation, and even the troubleshooting processes are made less complex, which translates to less training time for the employees.

Further, software integrated machines have the ability to be linked to the factory network for remote monitoring, data collection, and analysis of machine performance and efficiency. With these features, the cost becomes reasonable as one is able to see and understand the productive capability of the machine.

Xingke Automation: A Leading Provider of Fastener Packing Machines

When thinking of these imperative features, highly quality handling, and packing machinery that keeps up with modern technology, Xingke Automation is a leader in this industry. As a company with a clear focus on the development and production of sophisticated packaging systems, Xingke provides a spectrum of fastener packaging machines suitable for various industries.

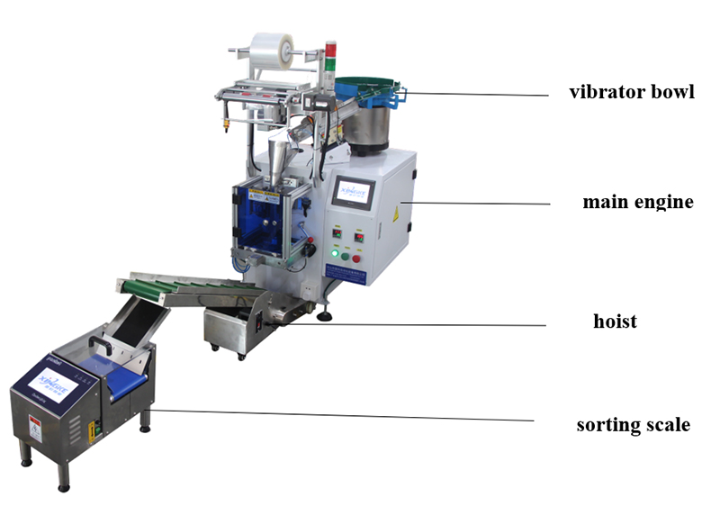

The fastener packing machines manufactured by Xingke’s company have a high-speed design, reliable performance, and sophisticated technology solutions. These machines are designed to fasten and pack all kinds of fastening elements ranging from screws to bolts, to cater to all products.

Some standout characteristics of the machines produced at Xingke Automation are as follows:

● High-Speed Packaging: Striving for the highest output, Xingke machines can fasten small hardware components at very high speeds to compete in the market by minimizing wasted time.

● Precision Control Systems: The machines manufactured by the company incorporate sophisticated counting and sorting systems that ensure that every package is perfectly filled with a specific number of fasteners.

● Versatility: Bags, boxes, and pouches are some of the different types of packaging that Xingke Automation provides, offering the client more choices in packaging.

● Durability: Machines made by Xingke Automation are composed of quality materials that are intended to the test of time with little maintenance needed.

● User-Friendly Interface: Xingke Automation incorporates intuitive control systems that allow operators to monitor and adjust the packaging process efficiently, reducing errors and downtime.

Whether you need a packing machine for fasteners for a small business or an industrial one, the machines from Xingke Automation contain everything to optimize your packaging.

Conclusion

When selecting a fastener packing machine, one has to take into account factors such as speed, accuracy, multipurpose functionality, dimensions, and other ergonomic characteristics of operation.

Well-structured and perfectly designed machines help boost productivity significantly and allow fasteners to be packed uniformly and efficiently. This, in turn, lowers the burden on your pocket and increases the customer satisfaction level.

In terms of companies that offer quality machines in the current market, Xingke Automation is a reliable option. Owing to our specific technologies and solutions that are oriented toward customers, Xingke Automation has the necessary tools you need to help you advance in the optimization of your process of packing fasteners.

Wait no more and view our products and services by simply going to our website today and be the first one to improve your packaging operations.

Selecting the right fastener packing machine allows you to achieve the maximum efficiency of production lines, and accurate product packing and helps your company to be competitive and ahead in this modern world.

Quick Links

Automatic Packaging Machine Products

Contact Xingke Automatic Packaging Machine Manufacturer

Contact: Mr Ren

Contact: Mr Ren

Email: office@xingkepacking.com

Email: office@xingkepacking.com Tel.: +86 13318294551

Tel.: +86 13318294551

Add: 9/F, Zhongchuang Industrial Park, No. 1 Xiaowusong Road, Huoju Development Zone, Zhongshan, Guangdong , China

Add: 9/F, Zhongchuang Industrial Park, No. 1 Xiaowusong Road, Huoju Development Zone, Zhongshan, Guangdong , China

Please Contact Us.

Xingke Machine is the professional automatic packaging equipment manufacturing expert.