Xingke Machine - Professional Automatic Packing Machine Manufacturer with 15+ years production experience.

Streamline Your Packaging Process with Hardware Packing Machines

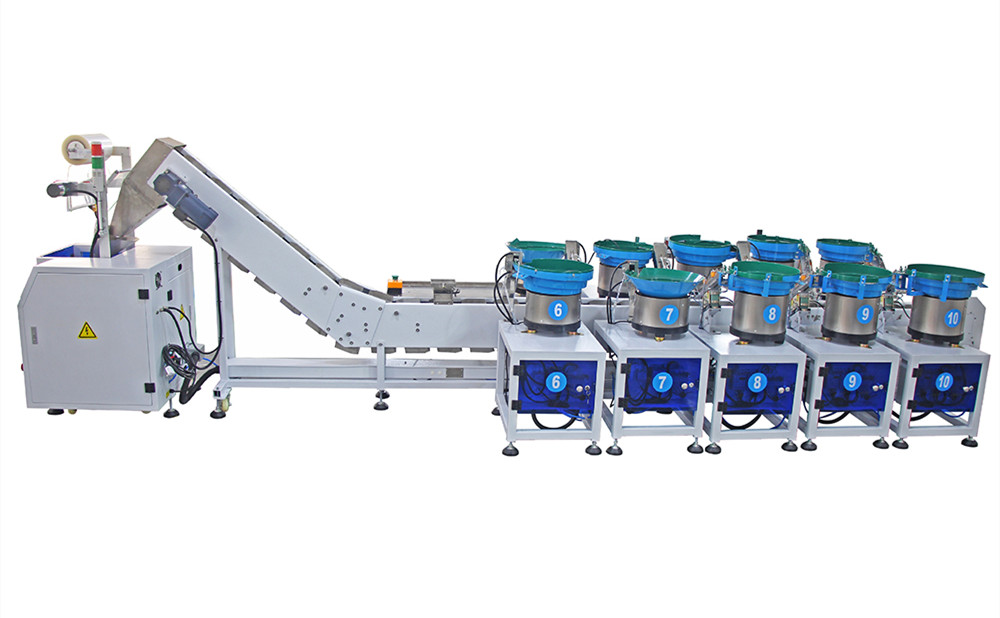

An industrially developed solution has been developed to package a wide variety of hardware components and accessories: the hardware packing machine. This equipment's adaptability may accommodate gaskets, frames, spring pads, springs, and a whole lot more. Hardware manufacturers rely on it heavily because of how well it handles lengthy components and items with unusual forms.

For example, the machine has an extra feeding conveyor for packing lengthy bolts and other such goods. The extra length of such products is precisely accommodated by the design of this conveyor. The lengthy bolts are easily placed into plastic bags and fed into the machine. This is an essential step since it guarantees that the main and most difficult component is packed firmly first before any smaller pieces can be added.

In addition to being able to handle long items, the hardware packing machine is just as good at managing products with odd shapes. Due to the complexity of these forms, the machine is subjected to rigorous testing. Manufacturers ensure the machine can handle these odd forms by doing several trials before we even consider delivering a quote to a prospective customer. These thorough tests show our dedication to providing a dependable and effective packaging solution.

Counting and weighing are the machine's two main packaging methods for hardware pieces. To guarantee that every bag has the precise amount or weight of components stated, these procedures are fundamental for precise packing. Things that need to be packaged with extreme precision, like screws, benefit greatly from this capability.

Furthermore, the machine showcases its adaptability by tolerating various forms of packing. The machine has a multi-head feeder so that it can pack screws into multiple types of boxes, such as plastic or carton. This complex component is essential to the machine's functionality because it properly counts the amount of items before they are loaded into the packaging. Maintaining quality control and customer satisfaction in the hardware sector relies on this degree of accuracy, which assures that each package includes the exact amount of goods.

Advantages of Using Hardware Packing Machines

Responding Effectively to Increased Demand

Hardware packing machine allows companies to handle increasing demand better, which is a major advantage. An uptick in demand is a sign of a successful company with happy clients and room to grow financially. Nevertheless, there may be difficulties brought about by this increase in demand. Rising production needs may cause personnel shortages, output delays, and higher labour expenses.

If we put speed ahead of accuracy, we risk losing money, missing deadlines, and lowering the quality of our products. Businesses risk losing customers to rivals if they can't stay up. In addition, if temporary workers leave for greener pastures, the investment in their training might be for nothing. A solution is provided by packaging machines, which increase manufacturing capacity and help organizations fulfill increasing needs without these problems.

Reducing Labor Costs

Costs associated with labor are major factors for the majority of companies. Payroll taxes, sick and holiday pay, training, and other perks influence these expenses. When companies have to pay employees extra during slow times between product runs or provide higher rates for asocial hours, it may cut into their earnings. This is in addition to the fact that hiring additional personnel to meet future growth isn't always ideal.

Because they need fewer personnel, packaging machines are a cost-effective solution. Because of this, companies may reorganize their workforce to focus on higher-value tasks like customer service, administration, or upkeep. Companies may increase output without sacrificing quality by automating the packaging process, reducing expenses.

Enhancing Quality Assurance

Inconsistencies may occur when humans are involved in the packing process. In addition to producing waste, mistakes like overfilling containers, breaking packaging, applying labels incorrectly, or not tightening lids enough may lead to unhappy customers. Extra quality assurance personnel and monitoring for repeated mistakes to ascertain the need for extra training are common responses to these problems. A more dependable and consistent option is to use hardware packing machine.

Machines are immune to the effects of boredom and exhaustion on human performance. Therefore, packing automation guarantees constant quality minimizes the danger of human mistakes, and reduces the need for rigorous quality inspections. Reduced waste and the expense of fixing errors are side effects of higher product quality and happier customers.

Types of Hardware Packaging Machines

There are numerous types of hardware packing machines, but we will name a few in this section.

Lamination Film Packaging Machine

For companies looking for a middle ground between total automation and human oversight, these machines strike the perfect combination of efficiency and adaptability. The semi-automatic operation guarantees accuracy and flexibility in packaging, making it ideal for wrapping diverse items in a lamination film.

Hardware Accessories Automatic Counting Packaging Machine

This machine mechanized the small hardware items being counted and packed; it was self-designed as precise, accurate and efficient. Its advanced technology ensures accurate counting and hassle-free packing for companies that handle large volumes of hardware components.

Hardware Furniture Fittings Packing Machine

This machine handles hardware furniture fittings and is customised to meet specific packing requirements. It has an adaptive design that reflects in a secure and neat packaging of fittings with varying shapes and sizes because it processes unique items.

Automatic Counting Coding Screw Packaging Machine

The revolutionary counting and coding features of this machine changed the screw packing forever. In short, automating the packaging of screws and ensuring each package is correctly labeled with the right number, helps to streamline processes in production while increasing accuracy.

Choose Quality, Choose Xingke

Xingke is a famous Chinese hardware packing machine manufacturer that provides excellent packaging solutions for businesses regardless of size. Years in business have taught us the particular needs and problems of effective and safe packing of hardware goods. Our equipment is equipped with the best technology and detailed precision workmanship to deliver precise performance every time.

Xingke has nuts, bolts, power tools, electronics and other machinery. Xingke provides high-quality equipment and good aftersales services, such as installation advice, operator training or fast technical support. Wrapping perfection with efficiency, customer satisfaction and company success is guaranteed when you select Xingke as the hardware packaging machine manufacturer.

Quick Links

Automatic Packaging Machine Products

Contact Xingke Automatic Packaging Machine Manufacturer

Contact: Mr Ren

Contact: Mr Ren

Email: office@xingkepacking.com

Email: office@xingkepacking.com Tel.: +86 13318294551

Tel.: +86 13318294551

Add: No. 11, South Qimin Road, Huoju Development Zone, Zhongshan, Guangdong, China.

Add: No. 11, South Qimin Road, Huoju Development Zone, Zhongshan, Guangdong, China.

Please Contact Us.

Xingke Machine is the professional automatic packaging equipment manufacturing expert.