Xingke Machine - Professional Automatic Packing Machine Manufacturer with 15+ years production experience.

The Production Process of the Packaging Machine

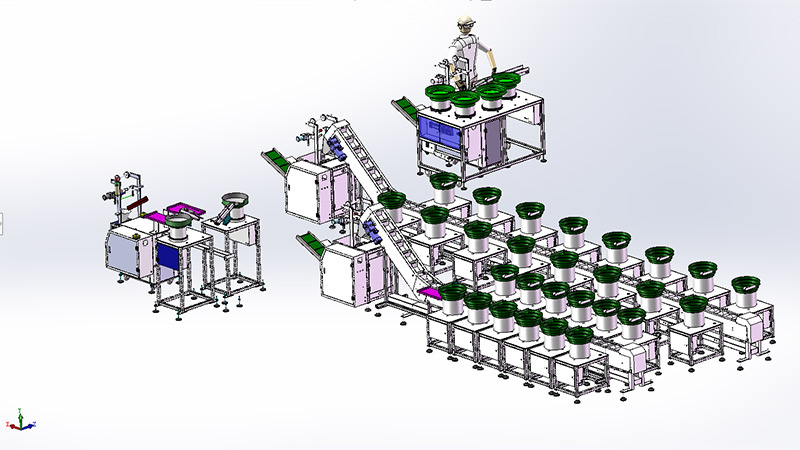

1.Program customization: Customize based on customer material information and requirements.

2. Professional docking: Focus on the packaging industry for 11 years, have a number of patents, one-to-one design by R&D personnel.

3.Model selection service: Abundant model room, customized model selection based on product technology.

4. Free proofing: Customer can send products upon request free proofing.

5.Vibrator bowl production: The automatic feeding vibrator bowl is customized according to the material, made of stainless steel to ensure the accuracy and smoothness of its feeding.

6.Installation : Assembly and commissioning by professional technicians. It can be shipped after stable operation and aging test.

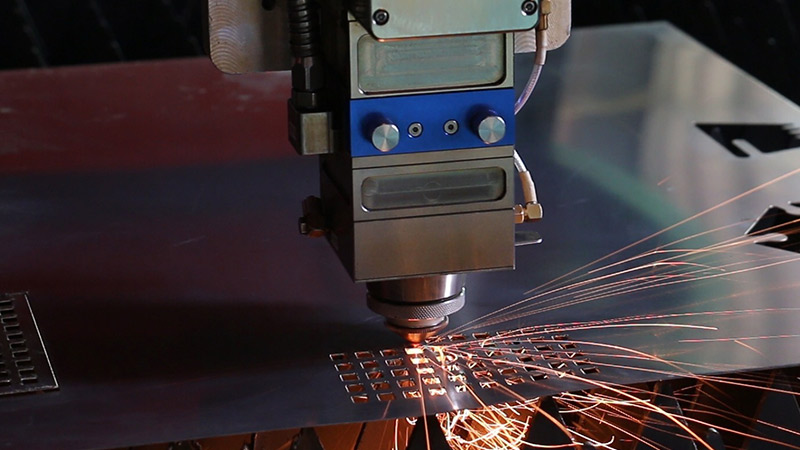

7. Precision processing: All sheet metal parts are made by laser cutting, and CNC machining using, to ensure the precision and beauty of each part.

8. After-sales service: Provide after-sales solutions within 24 hours, and the equipment is guaranteed for 1 year.

9. Shipping service: With more overseas shipping experience, can provide any delivery services such as FOB, CIF, CNF, DDU, DDP, etc., to ensure product arrival time; FedEx, TNT, UPS, DHL for your choose.

1.Organize information according to customer requirements.

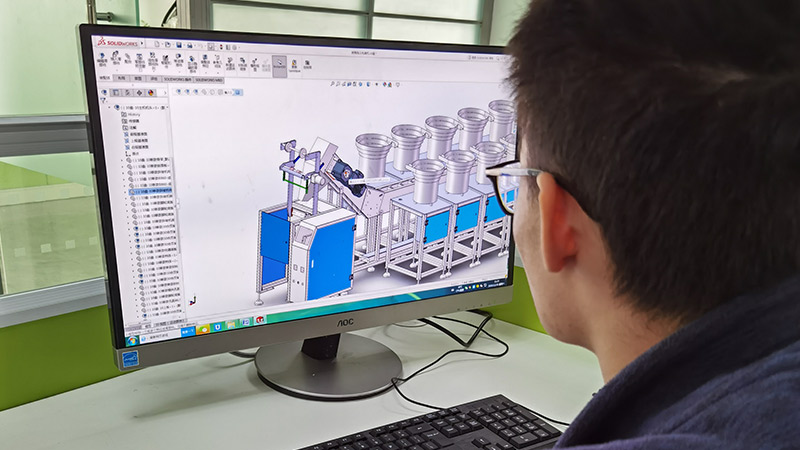

2.The designer makes 3D/2D design drawings, simulates the operation, and make the file.

3. After the customer confirms , the processing department starts to process the sheet metal shell and parts according to the drawings, and the vibrator bowl workshop starts to produce the vibrator bowl.

5. After the parts and vibrator bowl are completed, the electrical engineer starts wiring the electrical connection cabinet, and at the same time the fitter begins to assemble the whole machine mechanism.

6. After the assembly is completed, the individual test of the number of points of each vibrator bowl station is started, and it needs to be operated independently and stably for more than 100 times, and then the whole machine is mixed test.

![The Production Process of the Packaging Machine 7]() 7. After the test is completed, start to simulate actual production according to the order information to check the stability and accuracy of the overall operation of the equipment.

7. After the test is completed, start to simulate actual production according to the order information to check the stability and accuracy of the overall operation of the equipment.8. After the simulated production is completed, the whole machine is subjected to aging test, and all stations are turned on for aging.

![The Production Process of the Packaging Machine 8]() 9. Start binding the wooden boxes. Before packing, the quality control staff will conduct final quality inspection, and determine the packing quantity and whether the accessories are completing according to the order.

9. Start binding the wooden boxes. Before packing, the quality control staff will conduct final quality inspection, and determine the packing quantity and whether the accessories are completing according to the order.

Quick Links

Automatic Packaging Machine Products

Contact Xingke Automatic Packaging Machine Manufacturer

Contact: Mr Ren

Contact: Mr Ren

Email: office@xingkepacking.com

Email: office@xingkepacking.com Tel.: +86 13318294551

Tel.: +86 13318294551

Add: 9/F, Zhongchuang Industrial Park, No. 1 Xiaowusong Road, Huoju Development Zone, Zhongshan, Guangdong , China

Add: 9/F, Zhongchuang Industrial Park, No. 1 Xiaowusong Road, Huoju Development Zone, Zhongshan, Guangdong , China

Please Contact Us.

Xingke Machine is the professional automatic packaging equipment manufacturing expert.