Xingke Machine - Professional Automatic Packing Machine Manufacturer with 15+ years production experience.

bag counting machine at Wholesale Prices | Xingke

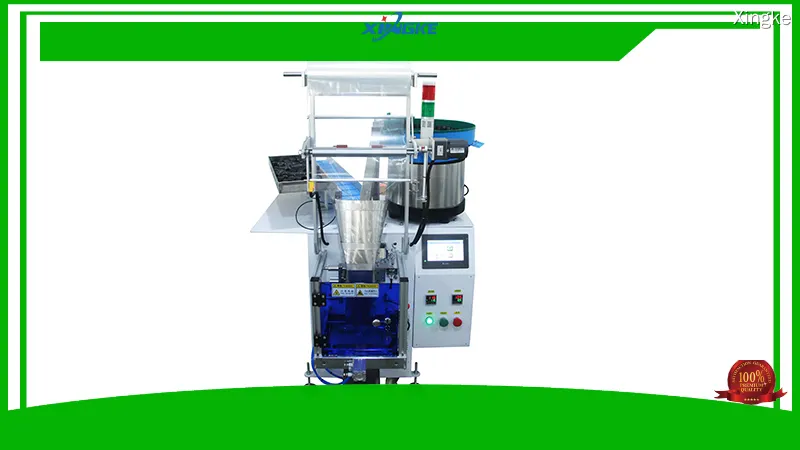

1) Technical characteristics

1. Automatic arranging, automatic counting, automatic filling, automatic packing, sealing function, output count.

2. Adopt intelligent temperature control system, stable temperature control, temperature can be adjusted according to needs.

3. The length of the bag can be adjusted, the total amount of the package can be adjusted, and the automatic alarm can be reached when the set number of times is reached.

4. After packing, the bag is uniform, neat, beautiful and firm. It can also be equipped with coding machine, check weighing, labeling machine, hoist and other expansion equipment.

2) Scope of application and functional features

1. This product is suitable for automatic packaging of a single kind of material, such as screws, nuts, flat pads, spring pads, toys, standard parts, etc. After automatic counting of vibration plate, the product will be filled to the molding machine for automatic packaging, and the hand throw belt is added for manual delivery of other materials mixed packaging.

2. It is suitable for "OPP/CPP/ lamination film" as sealing material.

After years of solid and rapid development, Xingke has grown into one of the most professional and influential enterprises in China. bag counting machine Xingke have a group of service professionals who are responsible for answering questions raised by customers through the Internet or phone, tracking the logistics status, and helping customers solve any problem. Whether you'd like to get more info on what, why and how we do, try our new product - New bag counting machine Price, or would like to partner up, we'd love to hear from you.bag counting machine It has the characteristics of stable operation, simple operation, convenient maintenance, high efficiency and energy saving, and has been widely used in many industries and fields such as food, beverage, medicine, daily necessities, tobacco and wine, hardware, chemical industry, and electronic machinery.

Xingke Xk-B861p hardware parts Counting Packing Machine offers several benefits in industrial and manufacturing settings where precision, efficiency, and accuracy are crucial. Here are some of the key advantages:

1. Accuracy and Precision: These hardware parts packing machines are designed to count hardware parts accurately, reducing the potential for human error that can occur with manual counting methods. This ensures that each package contains the exact number of parts required, meeting customer specifications and quality standards.

2. Efficiency and Speed: Hardware parts counting packing machines can significantly increase packing efficiency and throughput compared to manual counting. They can count and pack parts at a much faster rate, thereby improving overall production efficiency and reducing labor costs.

3. Consistency and Uniformity: By automating the counting and packing process, these machines ensure consistency in the quantity of parts packed in each batch or order. This uniformity is essential for maintaining quality control and meeting customer expectations.

4. Reduction in Packaging Waste: Automated machines often optimize the use of packaging materials, minimizing waste and reducing packaging costs. They can pack parts into standardized packaging formats efficiently, maximizing space utilization and reducing excess packaging.

5. Inventory Management: These machines often integrate with inventory management systems, providing real-time data on parts inventory levels. This helps in maintaining optimal stock levels, reducing stockouts, and improving overall inventory control.

6. Operational Safety: Automating the counting and packing process reduces the physical strain and potential ergonomic risks associated with repetitive manual tasks. This contributes to a safer working environment for employees.

7. Flexibility and Versatility: Many hardware parts counting packing machines are adaptable to various types and sizes of hardware parts, from small screws and bolts to larger components. They can often be programmed or adjusted for different packaging requirements or production scenarios.

8. Traceability and Documentation: Advanced machines may offer features such as labeling, barcode scanning, or RFID tagging capabilities. This facilitates traceability throughout the supply chain and simplifies documentation for shipping and inventory management purposes.

Overall, investing in a hardware parts packing machine can lead to improved productivity, reduced costs, enhanced quality control, and better customer satisfaction in manufacturing and distribution operations that deal with hardware components.

Equipment Model: XK-B861P

Counting Method: Manual placement

Bag Size: Width 40-140 length 200 (conventional 140)

Packing Speed: 1-60 bags/min

Sealing Shape: Stripe, back sealing/three side sealing (conventional back sealing)

Voltage Power: 220V/50HZ P≈0.6KW

Air Supply: 0.4-0.8MPA

Bag Mouth Shape: Figure cutter tooth shape

Dimensions: Length 1300mm/ width 1020mm/ height 1500mm

Weight: About

Quick Links

Automatic Packaging Machine Products

Contact Xingke Automatic Packaging Machine Manufacturer

Contact: Mr Ren

Contact: Mr Ren

Email: office@xingkepacking.com

Email: office@xingkepacking.com Tel.: +86 13318294551

Tel.: +86 13318294551

Add: 9/F, Zhongchuang Industrial Park, No. 1 Xiaowusong Road, Huoju Development Zone, Zhongshan, Guangdong , China

Add: 9/F, Zhongchuang Industrial Park, No. 1 Xiaowusong Road, Huoju Development Zone, Zhongshan, Guangdong , China

Please Contact Us.

Xingke Machine is the professional automatic packaging equipment manufacturing expert.