Xingke Machine - Professional Automatic Packing Machine Manufacturer with 15+ years production experience.

Latest automated packaging machine factory | Xingke

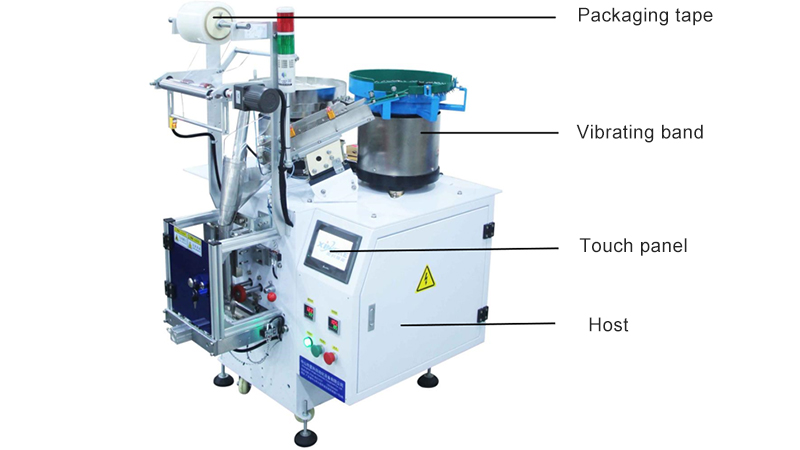

1) Technical characteristics

1. Automatic filling, automatic packing, sealing function, output count.

2. Adopt intelligent temperature control system, stable temperature control, temperature can be adjusted according to needs.

3. The length of the bag can be adjusted, the total amount of the package can be adjusted, and the automatic alarm can be reached when the set number of times is reached.

4. After packing, the bag is uniform, neat, beautiful and firm. It can also be equipped with coding machine, check weighing, labeling machine, hoist and other expansion equipment.

2) Scope of application and functional features

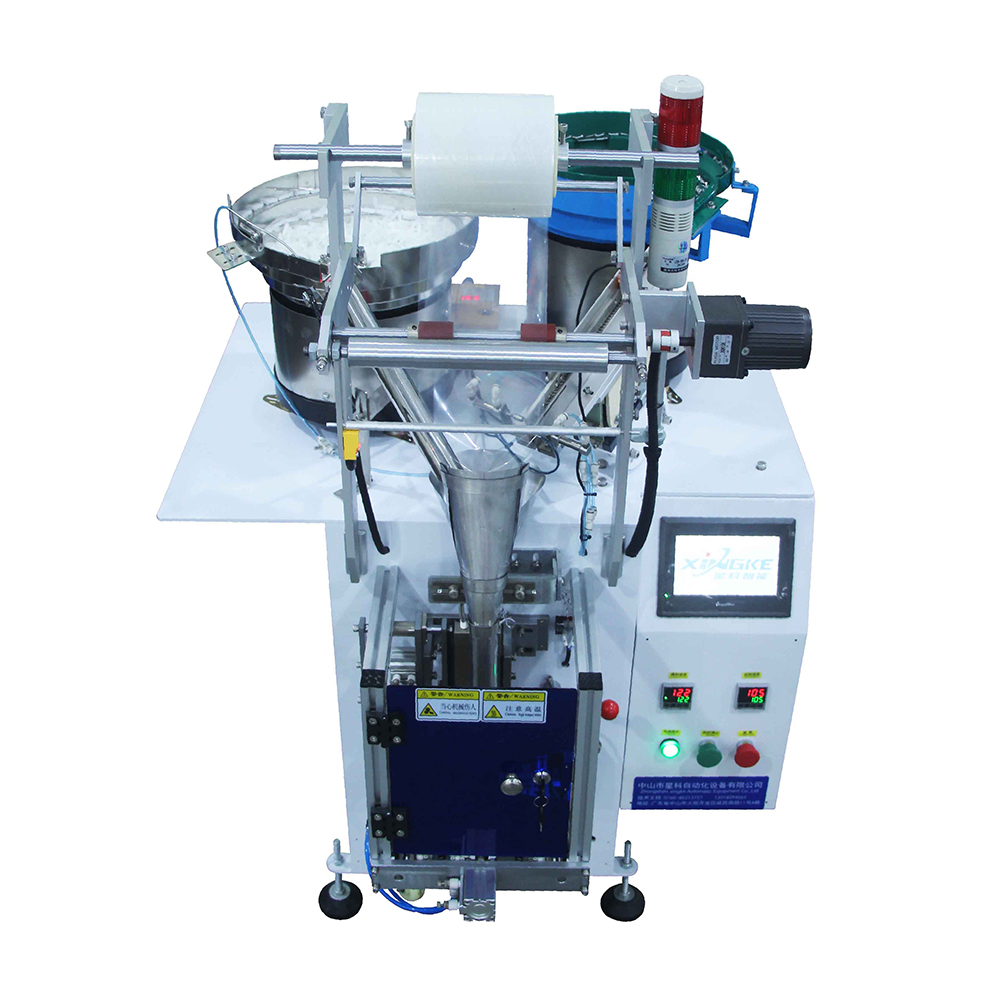

1.It is suitable for automatic mixing or separate packaging of 2 kinds of materials, such as screws, nuts, plain washers, spring washers, toys, standard parts, etc. this product uses chain bucket turns box, vibrator bowl, automatic counting on materials to box, the bucket will to molding machine automatic packaging materials for the products, also can use artificial into other materials mixed packing equipment free space.

2. It is suitable for "OPP/CPP/ lamination film " as sealing material.

Always striving toward excellence, Xingke has developed to be a market-driven and customer-oriented enterprise. We focus on strengthening the capabilities of scientific research and completing service businesses. We have set up a customer service department to better provide customers with prompt services including order tracking notice. automated packaging machine We will do our best to serve customers throughout the whole process from product design, R&D, to delivery. Welcome to contact us for further information about our new product automated packaging machine or our company.Our automated packaging machine adopts a user-friendly operation interface, and relevant parameters such as speed, bag length, and cut point position will be intuitively displayed on the touch screen, and the machine can respond quickly when you click to run the machine, and the operation is very simple.

Equipment Model: XK-B862

Product Name: Two Vibrator Bowl Packaging Machine

Counting Method: Optical fiber counting/blocking and putting

Bag Size: Width 40-140, length less than 200 (conventional 140)

Packing Speed: 1-60 bags/min

Sealing Shape: Stripe, back seal/three side seal (usually back seal)

Voltage Power: 220V/50HZ P≈0.6KW

Air Supply: 0.4-0.8MPA

Bag's both Sides : Figure cutter tooth shape

Dimensions: Length 1100mm/ width 1000mm/ height 1550mm

Weight: About 180KG

Quick Links

Automatic Packaging Machine Products

Contact Xingke Automatic Packaging Machine Manufacturer

Contact: Mr Ren

Contact: Mr Ren

Email: office@xingkepacking.com

Email: office@xingkepacking.com Tel.: +86 13318294551

Tel.: +86 13318294551

Add: 9/F, Zhongchuang Industrial Park, No. 1 Xiaowusong Road, Huoju Development Zone, Zhongshan, Guangdong , China

Add: 9/F, Zhongchuang Industrial Park, No. 1 Xiaowusong Road, Huoju Development Zone, Zhongshan, Guangdong , China

Please Contact Us.

Xingke Machine is the professional automatic packaging equipment manufacturing expert.